Maybe You Want

Choose the right scaffolding frame - choose ZHONGHONG

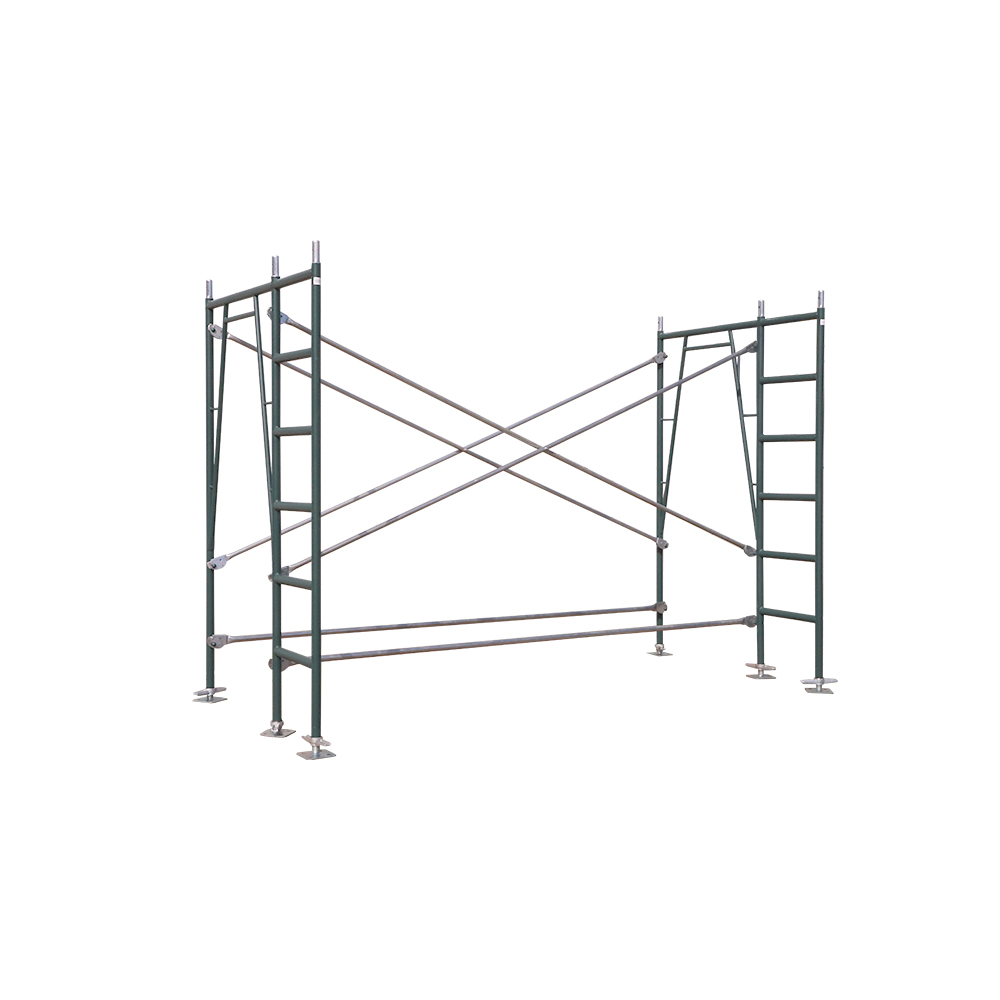

We offer spare replacement scaffolding frames in Safeway, Waco, Bil-Jax and Snap-On Style styles.

As a scaffolding frame manufacturer, we have the ability to produce bespoke and high quality scaffolding frames, as well as a large stock of scaffolding frames. If you are buying new scaffolding, we are confident that we have the best scaffolding frame for your next project. if you want to add to your scaffolding inventory, we can provide matching scaffolding frames for your existing scaffolding. we offer ladder frame scaffolding and walk through frame scaffolding, as well as frames in different heights and widths. We sell high quality scaffolding frame products at wholesale prices.

ladder frame scaffolding is defined as a temporary elevated platform which is supported or suspended. It is used for supporting an employee, materials, or both.

Color: Red, blue, green, yellow, customizable

Minimum Quantity: 1*20GP

Product Delivered Quantity: 500

Construction, Engineering

Material: Q235 Steel, Q355 steel

Comon size : 5'X6'4″

Surface Treatment: Flame Plating/ Electro galvanized

Product Size

| Steel Frame Scaffold with Ladder | ||

| Dia*wall thickness | Size(mm)=length*width | KG |

| φ41.3*2.3 | 1371*2032 | 24.5 |

| φ41.3*2.3 | 1371*2641 | 31.4 |

| φ41.3*2.3 | 1371*3251 | 36.2 |

Frame Scaffold is a universal scaffold, compared with the ordinary frame, more convenient to use, often used for residential contractors, painters, etc., can also be superimposed, used for large construction work with versatility, economy and ease of use.

This type of steel Frame Scaffold scaffolding system is composed of a frame, crossbeams, connecting pins, steel plates, and then a horizontal steel bar, the bottom of which is inserted into a jack base with casters.

Steel is the most commonly used scaffolding material. Steel Frame Scaffold is extremely durable and strong, comparable to other scaffolding materials such as aluminium and wood. Scaffolding is a temporary structure that is used in all areas of construction, maintenance and repair work. This is because it offers the opportunity to work in high and/or remote areas. It is mainly made of steel, bamboo or timber. The main purpose of erecting scaffolding is to provide a platform for workers to work at different heights or to lift materials for immediate use.

Steel Frame Scaffold, otherwise known as ‘tubular scaffolding’, has a similar structure to double and single scaffolding. The difference lies in the material used. Unlike single and double scaffolding, steel scaffolding uses steel tubing rather than timber, and instead of rope lashing, it uses steel couples. The standards are fixed into the ground using a base plate.Steel Scaffolding Also known as scaffold or staging, scaffolding is a term that refers to part-time structures used to support crews and various construction materials during the erection or repair or various buildings and other structures.

Affordable steel scaffolding frames and towers are available in ladder or walk-through frames and in a wide range of heights and widths to suit almost any construction project. Frames can easily be stacked vertically and attached horizontally to suit your application. Accessories such as wheels and levelling jacks allow you to erect scaffolding on a wide range of terrains and uneven surfaces.

Metal Frame Scaffold allows workers to safely, conveniently access high and difficult locations during various construction projects. It does so through the use of three basic structural elements:

Vertical steel or aluminum tubes of Frame Scaffold that are placed throughout the structure to support it and hold it up. These tubes all are balanced by a square base plate, which spreads the weight around evenly so there’s no risk of collapse.

Horizontal tubes of Frame Scaffold that connect various standards and further supplement balance.

Different horizontal tubes placed perpendicularly to the ledgers. These are meant to add strength and support for standing platforms, which may be placed on several levels of scaffolding simultaneously.

Steel Frame Scaffold has a higher carrying capacity and provides a firm steady standing structure. It can remain strong even during intense weather conditions such as wind and heavy rain.

Compared to other materials, steel is durable and more economical in the long run. It also has more fire-resisting capacity and is far more suitable and safe for those working at height.

To make work easy and safe, it is also equipped with safety ropes, decorative plates and other supplies. Where workers need to work with electricity, there is insulation to reduce any possible danger due to electrocution. Workers should always check all loose parts when using steel scaffolding and must also check what they are wearing. All safety equipment must be worn at height. Workers need to ensure that the platform is working effectively when using a mobile platform for lifting and lowering.

Steel Frame Scaffold provides a stable and solid stand. Steel scaffolding can withstand the loads and stresses of heavy rain or strong winds. In fact, steel will remain as strong and durable as ever, even in harsh environments such as earthquakes.

Steel Frame Scaffold offers longer durability.

Steel Frame Scaffold can be easily assembled and disassembled, increasing efficiency.

The leftover steel is the raw material needed for the scaffolding. As such, it helps to solve the waste problem and promotes a greener environment. In contrast, if scaffolding were made of wood, we would soon be short of trees, which are important for our survival and to beautify our planet (Earth). Steel does not need to cut down and waste trees.

Frame Scaffold is vital to have a reliable and solid foundation. In the future, steel scaffolding will be the right choice in order to improve operational efficiency and worker safety.

Shop quality ladder Frame Scaffold?Choose ZHONGHONG! As a ladder frame scaffolding manufacturer,ladder frame scaffolding wholesale,ladder frame scaffolding factory, we can produce scaffold as heavy duty ladder frame scaffolding as you hoped, Also It is much more reasonably wholesale priced than any of the competitors. Buy ladder frame scaffolding for many things. we provide fast and knowledgeable service of ladder frame scaffolding. Come to for any other scaffolding or accessories that you might be in need of in the future. ZHONGHONG are specializing in export Frame Scaffold and scaffolding accessories, including door scaffolding, disc scaffolding, aluminum scaffolding, pull rod, steel shoring, aluminum shoring, iron pedal, all-aluminum pedal, aluminum wooden pedal, and scaffolding accessories.

Accessories

Which actual metal pieces are used to create the above elements, along with platforms and floors? There are a few basics to know:

Tubes: When made from steel, tubes for scaffolding are generally created using hot-rolled steel, though certain special applications will require a glass fiber in a nylon matrix.

Couplers hold tubes together in scaffolding through one of a few different formats.

Also called decking, platforms made from either basic wood or possibly steel or aluminum will be used to create scaffolding floors. Even when wood is used, metal is required for use as protective plates on the ends of the wood pieces.

As we noted above, steel and aluminum are the two most common metal types used for scaffolding. The primary benefit of using steel over aluminum is the weight and durability – steel is about three times as heavy as aluminum, and many feel it provides a stronger and more durable support.

Scaffolding is of great use in several areas of construction, including the following formats:

Suspended scaffolding: Scaffolding that hangs down from the roof of a building, often in circumstances where creating a base is impossible or access from the ground is limited.

The more common type, built from the ground up. This is the safest and most convenient form of scaffolding, and recommended where possible.

Rolling scaffolding: Almost the same as supported scaffolding, but with castor wheels on the base instead of a stable structure. This allows the scaffolding to be moved to different areas of the structure if needed, but also for locking the wheels in place as appropriate so there’s no danger of movement.

For more on scaffolding, or to learn about any of our steel products, speak to the staff at Wasatch Steel today.

Employees working above 10 feet (3.1 m) on a ladder jack scaffold must be protected from fall hazards by a personal fall arrest system .The front edge of all platforms must not be more than 14 inches (36 cm) from the face of the work, unless guardrail systems are erected along the front edge and/or personal fall arrest systems are used.

|  |  |  |

| Connecting Rod | Adjustable Base | Tie Rods | Connection Method |

Steel is the most commonly used material for scaffolding. Steel Frame Scaffold is extremely durable with high strength and is comparable to other scaffolding materials such as aluminum and wood.

Frame Scaffold is a temporary structure that is used in various areas of construction, maintenance and repair work. This is because it provides access to work in locations that are high and/ or remote. Predominantly, it is made from steel, bamboo or timber. The main purpose of erecting scaffolding is to provide a platform for a worker to work at different heights, or to lift materials for immediate use.

There are several main types of scaffolding: single scaffolding, double scaffolding, steel scaffolding and cantilever scaffolding.

Steel scaffolding

Steel scaffolding, otherwise known as ‘tubular scaffolding’, has a similar structure to double and single scaffolding. The difference lies in the material used. Unlike single and double scaffolding, steel scaffolding uses steel tubing rather than timber, and instead of rope lashing, it uses steel couples. The standards are fixed into the ground using a base plate.

Single scaffolding

Single scaffolding is commonly made from bamboo or timbers and features a series of vertical standards firmly fixed into the ground in a row and parallel to the construction or building wall. Rope lashing is used to tie the standards with horizontal ledgers.

Double scaffolding

Double scaffolding is commonly used in stone masonry as it is stronger than single scaffolding. Unlike single scaffolding, double scaffolding has two rows of standards that are fixed into the ground. The first row is fixed close to the wall, and the second is fixed 1.5m away from the first row.

Cantilever scaffolding

Cantilever scaffolding is used when it’s not possible to fix standard into the ground, or if construction work is being carried out on the side of a busy road or street, or if it’s being carried out at a high level on a tall building.

Steel Frame Scaffold has a higher carrying capacity and provides a firm steady standing structure. It can remain strong even during intense weather conditions such as wind and heavy rain.

Compared to other materials, steel is durable and more economical in the long run. It also has more fire-resisting capacity and is far more suitable and safe for those working at height. It is also widely used in the construction industry because it offers the greatest safety for workers.

This type of scaffolding can also be erected and dismantled quickly in comparison to timber scaffolding, which helps save construction time.

Foundation preparation → Placement of matting → Placement of base → Vertical two-bay single-piece gantry → Installation of cross bars → Installation of scaffolding boards → Repeat the process of installing gantry, crossbars and scaffolding boards on this basis.

(1) All materials used in the erection of high-rise scaffolding must meet the quality requirements.

(2) The foundation of high-rise scaffolding must be solid, calculated before erection to meet the load requirements, and erected according to the construction specifications, and drainage measures.

(3) The technical requirements for scaffold erection should be in accordance with the relevant specifications.

(4) Great importance must be attached to various construction measures: scissor bracing, tie points, etc. should be set up as required.

(5) Horizontal closure: should be from the first step, every step or two steps, full laying scaffolding board or scaffolding fence, scaffolding board along the long direction of laying, joints should overlap resting on the small horizontal bar, forbidden to appear empty headboard. And in the wall between the pole and the wall every four steps to lay a unified long safety bottom fence.

(6) Vertical closure: from the second step to the fifth step, each step is required to set up a 1.00m high protective kind of railing and foot barrier or set up a net on the inside of the outer row of poles, and the protective poles (net) are fastened with the poles; above the fifth step, in addition to setting up protective blocking poles, all safety fences or safety nets should be set up; in the street or densely populated areas, all safety fences or safety nets should be set up on the outside from the second step.

(7) Scaffolding should be erected more than 1.5m above the top of the building or the operating surface and be enclosed.

(8) The steel pipes, fasteners, scaffolding plates, and connection points on the erected scaffolding shall not be removed at will. If necessary during construction, they must be agreed by the person in charge of the site and effective measures must be taken to restore them immediately after the process is completed.

(9) Before the scaffolding is used, it should be checked and accepted by the person in charge of the site, and only after it has passed the inspection and filled in the delivery sheet can it be used. During the construction process, there should be professional management, inspection and warranty, and regular subsidence observation, abnormalities should be found in time to take reinforcement measures.

(10) When dismantling scaffolding, check the connection with the building first, and clear the scaffolding of stored materials, debris, etc., from top to bottom, according to the order of first installed and then dismantled, after installed and then dismantled, the dismantled materials should be uniformly passed down or lifted to the ground, step by step. No step demolition method is allowed, it is strictly forbidden to throw down or use the push (pull) down method of demolition.

Shop quality ladder Frame Scaffold?Choose ZHONGHONG! As a ladder frame scaffolding manufacturer,ladder frame scaffolding wholesale,ladder frame scaffolding factory, we can produce scaffold as heavy duty ladder frame scaffolding as you hoped, Also It is much more reasonably wholesale priced than any of the competitors. Buy ladder frame scaffolding for many things. we provide fast and knowledgeable service of ladder frame scaffolding. Come to for any other scaffolding or accessories that you might be in need of in the future. ZHONGHONG are specializing in export Frame Scaffold and scaffolding accessories, including door scaffolding, disc scaffolding, aluminum scaffolding, pull rod, steel shoring, aluminum shoring, iron pedal, all-aluminum pedal, aluminum wooden pedal, and scaffolding accessories.

Video